Metro has specialized in manufacturing continuous length rubber tank stripping gaskets for decades. Tank stripping gaskets are slit-to-width rolls of rubber with holes punched at precise uniform intervals, perfectly suited to sealing between bolted or riveted panels of medium to large sized tanks, as well as sealing large rectangle flanges with uniform holes. Metro is equipped to manufacture virtually any type of rubber, any width, and any hole size or spacing configuration with very few limitations.

Available Tank Stripping Materials

Metro carries several varieties of rubber suitable for most storage tank sealing applications. Popular varieties include Neoprene for general purposes, Nitrile Rubber (Buna-N) for petroleum products, and FDA approved white nitrile that is also good for general purpose food and medical products storage. The superior weather resistance of EPDM also makes it a good economical general purpose tank sealing material. Silicone rubber tank stripping is suitable for both low and high temperature extremes as well as food and medical products, while Fluoro-elastomer rubbers like Viton ® are suitable for both high temperatures and chemically volatile environments.

Reinforced Bolted Tank Stripping

Another feature MI offers is cloth inserted rubber tank stripping. Available in numerous insert options, the supporting layer of cloth or nylon inhibits rubber from extruding under pressure without compromising its ability to conform and seal the surfaces. MI can also manufacture punched tank stripping out of sponge rubber, foam, plastic, and various non-rubber gasket sheeting materials.

These are just a few general varieties of rubber types MI has available for tank sealing gaskets. In addition to numerous other classes, there is also a full menu of cost and performance options available. Narrowing this down to viable options usually is fairly simple, and we will gladly supply all the specifications, cost information, and samples necessary for an informed decision to be made.

These are just a few general varieties of rubber types MI has available for tank sealing gaskets. In addition to numerous other classes, there is also a full menu of cost and performance options available. Narrowing this down to viable options usually is fairly simple, and we will gladly supply all the specifications, cost information, and samples necessary for an informed decision to be made.

Available Sizes & Thickness

The combination of material thickness and hardness are the primary elements affecting the conformance of a seal to the tank panel surfaces (i.e. a thicker, softer material will be more inclined to seal irregular surfaces with less torque). However, greater thickness is also a detriment for two reasons, cost and weight. Since these rolls must be carried to often high or otherwise difficult to reach areas, thinner material allows more length of seal to be carried on a roll for less weight during construction of the tank. Longer rolls also yield less downtime for getting new rolls.

Typically, our clients find thicknesses between 1/16″ (.0625) and 1/4″ (.250) suitable for most tank sealing applications, with 3/32″ being a popular choice. This, however, is not a limitation, as MI can easily apply the same processes to thinner and thicker varieties of rubber and other materials.

Hole Shapes, Sizes, and Spacing

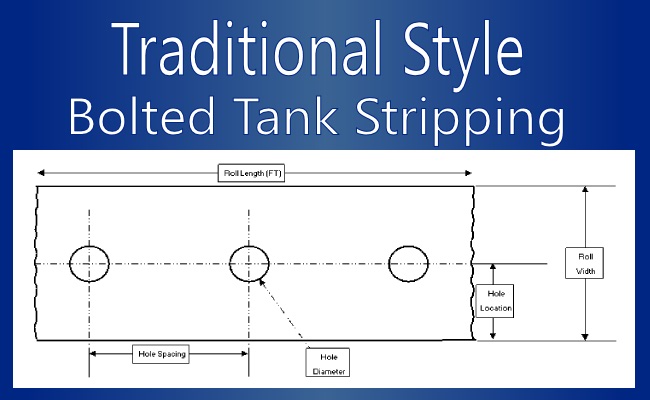

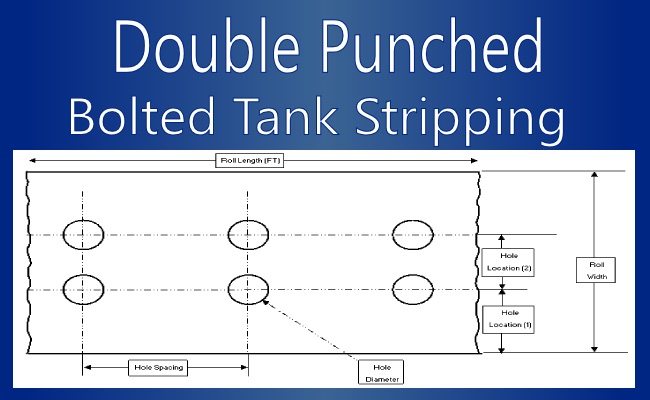

MI features its own efficient and cost-effective WaveSeal™ line of continuous length punched gasket stripping, plus single and double-punched varieties (see graphic to right) as standards, but can manufacture virtually any hole pattern, and can even supply oval, square, or alternate shaped holes. Of course, all rubber materials are available in slit-to-width rolls without any holes, as well.

Hole diameters are only limited by the combination of that and other dimensions, particularly material thickness, width, and spacing between the holes. As a rule of thumb, holes must be dimensioned at a minimum of material thickness plus 50% for both diameter and space between them and the material edge, but this is not a hard limitation.

Seal Length & Width

We could conceivably manufacture continuous length tank seals in widths as low as 1/2″ or as wide as 60″ inches of some materials, which means about whatever any one could want. Like material thickness, greater seal width may improve sealing effectiveness, but also increases cost and weight.

one could want. Like material thickness, greater seal width may improve sealing effectiveness, but also increases cost and weight.

Tank stripping is usually sold by the lineal foot, which is generally determined by the uncut roll size, which varies by thickness and variety between 25 and 300 foot lengths. Naturally, we can generally cater to special requirements on roll length.

Dimensional Tolerances

Tolerances vary according to material and dimension specifications, but typically runs around +/- .015 inches on key dimensions like width and hole diameter. Spacing is generally defined in two ways, first as the distance and tolerance between any two holes, typically +0.015″/-0.031″, and then further as the maximum variance allowed over a pre-defined length like 8 feet. The latter measure prevents misalignment of holes over the length of a panel that create bunching up or stretching.